- 返回顶部

- 400-0988-567

- 在线咨询

- 微信二维码

popular articles

Hour service hotline

HOUR SERVICE HOTLINE

Address:Dalin Industrial Zone, Shifan Town, Yueqing City, Wenzhou, Zhejiang, China

Phone:0577-62307017

Fax:0577-62309158

Mobile phone:13867716888

Mailbox:yqdeshun@163.com

Hotline:400-0988-567

The chamfering machine is a small precision machine tool specially used for burrs of mold manufacturing, hardware machinery, machine tool manufacturing, hydraulic parts, valve manufacturing, chamfering of textile machinery, and milling and planing. The use of fast machine chamfering is a trend in the development of the mechanical industry. It overcomes the shortcomings of existing mechanical and electric tools, and has the advantages of convenience, speed and accuracy. It is the best choice for chamfer cutting of metal objects.

According to the chamfer, it is divided into straight chamfer and curve chamfer:

It is a special tool for chamfering the groove on the front end surface of the welding. It solves the shortcomings such as flame cutting, grinding machine grinding and other operations, such as irregular angle, rough surface and large working noise. It is easy to operate. Angle standard, smooth surface and other advantages, with the advantages of light weight groove and high durability and convenient operation. It is very suitable for steel structure, boiler, pressure vessel, equipment manufacturing, shipbuilding, power, mold, chemical, petroleum engineering, metallurgy, head, iron tower, aerospace and other welding manufacturing fields.

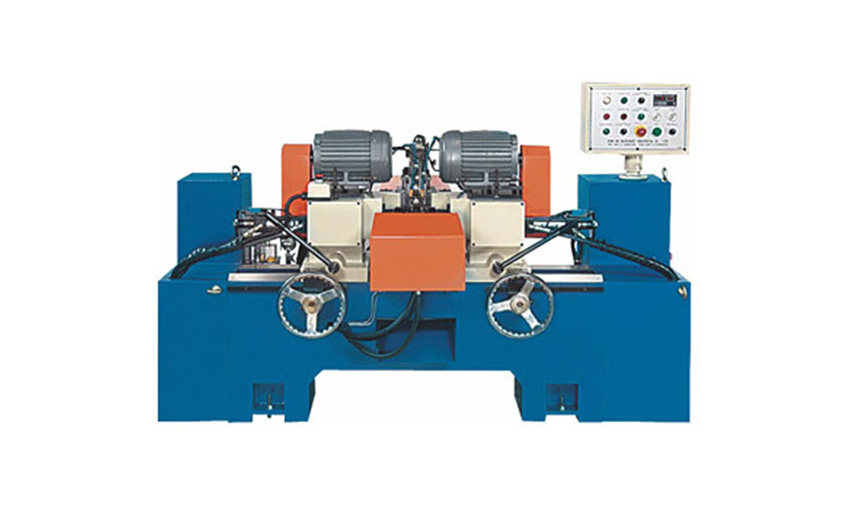

The composition of common chamfering machines:

Portable chamfering machine: mainly consists of three-phase motor, start switch, shell casting, support baffle, scale bar, humanized handle. It consists of milling cutters and other components. The principle is to chamfer the workpiece by driving the blade on the hob cutter.

Portable automatic walking chamfering machine: mainly by mobile walking frame, three-phase motor, turbine, vortex deceleration device, controller: start switch, emergency stop button, reverse button, magnetothermal protection, shell casting, support wheel The composition of the angle wheel and the like is based on the principle that the motor drives the overall rinsing cutter head through the reducer, and the chamfering operation is performed by the cutter wheel rolling. The small plate steel plate is self-propelled, and the large plate machine automatically walks.

Desktop chamfering machine: It consists of the body, the outer corner chamfering table, the positioning bracket, the inner corner chamfering table, the inner corner turning head, the outer corner turning head, the motor and the transmission mechanism. The inner and outer corners are rotated to rotate the cutter head, and the lower end shaft portion is provided with a transmission mechanism, and the vertical angle of the inner corner chamfering table is at the inner corner of the cutter head. The inner corner cutter head exposes the inner corner rotation cutter head, and is located under the outer corner rotation cutter head directly above the positioning bracket. The side groove is combined with the outer corner cutter head open hole of the outer corner chamfering workbench, the outer end of the outer corner rotary cutter head is exposed, and the outer corner cutter head is provided with a lifting device, and a lifting device is arranged between the outer corner chamfering worktable and the horizontal upper plate of the body. The outer corner chamfering table is vertically raised and lowered, so that the outer corner of the outer corner cutter can be adjusted by rotating the cutter head.

scan it

scan it scan it

scan it