- 返回顶部

- 400-0988-567

- 在线咨询

- 微信二维码

Product Categories

Hour service hotline

HOUR SERVICE HOTLINE

Address:Dalin Industrial Zone, Shifan Town, Yueqing City, Wenzhou, Zhejiang, China

Phone:0577-62307017

Fax:0577-62309158

Mobile phone:13867716888

Mailbox:yqdeshun@163.com

Hotline:400-0988-567

After a long period of research, the company has developed a new generation of pipe cutting machines. Compared with the fundamental problem of cutting pipe performance and single function in the pipe cutting machine industry for decades. This machine adopts the latest hydraulic positioning, servo system feeding and high-efficiency motor to improve the accuracy and stability. It mainly uses imported electrical appliances such as Siemens to ensure the reliability of the machine for a long time. It can cut copper, .......

YJ-200HQ automatic pipe cutting machine overview

After a long period of research, the company has developed a new generation of pipe cutting machines. Compared with the fundamental problem of cutting pipe performance and single function in the pipe cutting machine industry for decades. This machine adopts the latest hydraulic positioning, servo system feeding and high-efficiency motor to improve the accuracy and stability. It mainly uses imported electrical appliances such as Siemens to ensure the reliability of the machine for a long time. It can cut copper, aluminum, iron and stainless steel with a diameter of 1mm to 40mm, a length of 5mm to 120mm, and a length of 100mm and a length of 0.05mm.

The advantages of this machine are as follows: 2.5 times to 3 times faster than the traditional pipe cutting machine, which indirectly reduces the labor input, reduces the management cost, and solves the damage of the metal to the human body. The use of a more stable hydraulic system fundamentally solves the problems of easy loss, high noise and instability caused by the pneumatic system.

Automatic stop function: automatic detection and shutdown when there is no material

Tool protection function: Automatically stop when the tool is not detected properly due to improper operation

Timely control: programming with Microwinv3.2

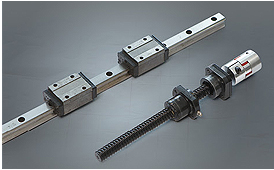

Optimized mechanical device: Reduces motion quality and minimizes wear by using linear guides and linear drives

Simple and comfortable operation design: advanced industrial engineering design and easy to understand operating system.

Technical Data Sheet

main motor power | 2.2KW | Control System | Siemens PLC | Cutting accuracy | ±0.05mm |

Feed motor power | 1.5KW | Roller screw | Japan THK | Cutting tool | Special tungsten steel saw blade |

System motor power | 0.75KW | Linear Guides | Japan THK | Rack length | 3000mm |

Total equipment power | 4.5KW | Cutting speed | 10-12 times / minute | Machine quality | 1045kg |

System pressure | 2.5-5Mpa | Cutting length | 5-120mm | Dimensions (mm) | 1700X1200X1000 |

Temperature requirement | -5℃-40℃ | Cutable outer diameter | Φ1-40mm |

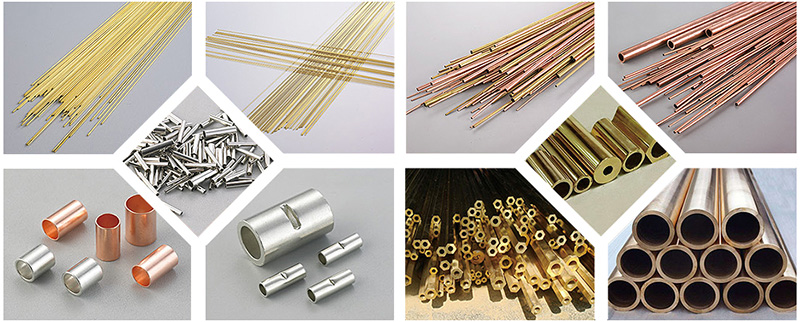

Cutting sample display

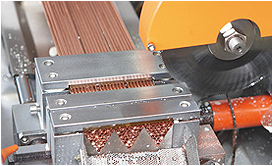

| Efficiency optimization The processing efficiency is increased by three times. This machine changes the traditional way of feeding up and down. It adopts a more reasonable horizontal feeding method. After the rigidity and vibration test, the best stroke can be used. It can cut 100-150mm at a time, which is equivalent to traditional cutting. The three stations of the pipe machine are equivalent to three times the processing efficiency. 2.5-3 times production efficiency Less manual input Less factory use area investment Lower processing energy cost rate optimization | ||

| Precision structure It is equipped with THK linear guides and screw rods imported from Japan to ensure the reliability of the machining stroke, so that your machining accuracy is accurate to ±0.05mm. It is used for linear reciprocating occasions and has a higher rated load than linear bearings. With a certain amount of torque, high-precision linear motion can be achieved with high load. High positioning accuracy and low wear Strong carrying capacity Adaptation tells the motion cut to greatly reduce the drive power | ||

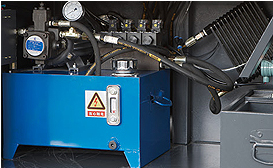

| Stable system The hydraulic system is used instead of the traditional pneumatic structure, which increases the service life and stability of the equipment. Not only easy to operate, but also beautiful in appearance. The hydraulic system unit is light in weight, compact in structure and low in inertia. Low noise and reduced energy costs Stepless speed regulation Overload protection The transmission movement is even and equal, and the speed is stable when the load changes. | ||

| Value-added services Reduce the cost of tool use by 30%. Considering the difficulties in the use of tools during the process, in order to make the use of our equipment and customers to enjoy the service of Deshun, we have tried many times to match the equipment. Tungsten steel saw blades are available at cost. Higher material requirements: special tungsten steel saw blade for higher service life Larger outer diameter: ∮160mm (150mm market) Thinner machining tool: thickness 0.7mm | ||

scan it

scan it scan it

scan it