- 返回顶部

- 400-0988-567

- 在线咨询

- 微信二维码

Product Categories

Hour service hotline

HOUR SERVICE HOTLINE

Address:Dalin Industrial Zone, Shifan Town, Yueqing City, Wenzhou, Zhejiang, China

Phone:0577-62307017

Fax:0577-62309158

Mobile phone:13867716888

Mailbox:yqdeshun@163.com

Hotline:400-0988-567

Special sawing action design: Concealed saw blade (safety) automatically cuts the material from the back to the front, and then the working platform is pulled away by the air compressor control, and the saw blade retreats to the origin. This feature is designed to avoid the smooth and precise surface of the material being machined during the machining process, which is affected by the smoothing and precision of the machining surface by the blade returning (retracting).

Yueqing Deshun Machinery Co., Ltd. is a company specializing in the production, processing and sales of automatic aluminum cutting machine, automatic pipe cutting machine, bus processing machine, double-head chamfering machine, hydraulic aluminum sawing machine and pneumatic pipe cutting machine. The comprehensive pipe cutting machine manufacturer; the ideal matching equipment manufacturer for cutting, forming, riveting and other processing technologies of various pipe profiles, providing the most comprehensive cutting machine customization plan consultation, pipe cutting machine price consultation; national unified service hotline: 400 -0988-567

Characteristic:

1. Automatic feeding, automatic positioning, automatic sawing and automatic fuel injection.

2, the longest feeding stroke of 1400mm/3000mm/6000mm, can be overlaid with 9999MM length automatic feeding sawing.

3, the use of servo motor to drive the ball screw, high precision.

4, man-machine touch screen, easy to operate, fault self-detection, screen display exclusion.

5, using CNC Fuji controller, computer control stability, electronic control components CE certification products.

6, saw setting function: can do 100 sets of memory size, group settings, each group can be set up to 12 sizes for sawing.

7. The computer will automatically record the processing report (such as the number of sawing, the moving mileage of the feeding table, the saw blade stroke and the feeding sawing time, the saw blade sawing life, etc.).

8. Special design fixture (two sets of upper pressure, two sets of lower pressure), suitable for irregular materials and materials can be placed side by side.

9, sawing method: linear sawing, suitable for processing wider, higher materials.

10, can do automatic sawing. Manual sawing is also available.

11, feeding mode: 1, step feeding. 2. Feeding over the cover. 3. Manual feeding.

12. The saw blade protection cover and the electric control box have the function of opening and breaking power protection, and the safety is higher.

Suitable for sawing and processing: aluminum profiles, copper, heat sinks, plastic steel materials, bakelite, acrylic, plastic products, wood and other non-metallic materials.

Function introduction:

1 Suitable for sawing non-ferrous metals, copper, aluminum, zinc, plastic, carbon fiber and other materials.

2 Especially suitable for building doors and windows, industrial aluminum, special-shaped materials.

The 3 frame adopts the reinforced design. The frame processing utilizes the gantry CNC machining center to form one time, and the feeding system is carefully designed to not damage the surface of the workpiece, and the feeding is smooth. Equipped with a stopper head/front end holder side clamp auxiliary/tail material lifting and feeding.

4 The main clamp design is more in line with the needs of the times. The fixed clamp and the secondary clamp are used to make the position retreat processing function, so that the saw blade can be cut without signs of retraction.

5 The main/sub-clamps are gantry-type clamped, and the side clamps are designed to be suspended. No fixtures are required for the shape of the workpiece.

6 sawing design is also unique, horizontal and horizontal cutting, cylinder feeding to make the equipment more stable.

7 control mode: PLC + touch screen.

8 feeding method: servo motor, precision screw drive.

9 working mode: servo motor / automatic feeding / tailings detection / material separation retraction.

10 cooling method: micro spray.

11 aluminum scrap recycling method: carefully designed single / double barrel high suction vacuum cleaner to make the workshop cleaner.

12 hydraulic system: independent embedded, easy to install and easy to maintain.

13 Gas storage: Built-in independent air reservoir, pressure detection device, to eliminate external factors, to ensure the normal operation of equipment, to ensure safety.

14 Transmission: The equipment is heavy-cut type, which is adjusted by the inverter and selects the reasonable spindle rotation number of the saw blade.

15 Lubrication system: Controlled by PLC, it provides regular lubrication for all parts of the screw and guide rail.

16 design has a strong three-dimensional effect.

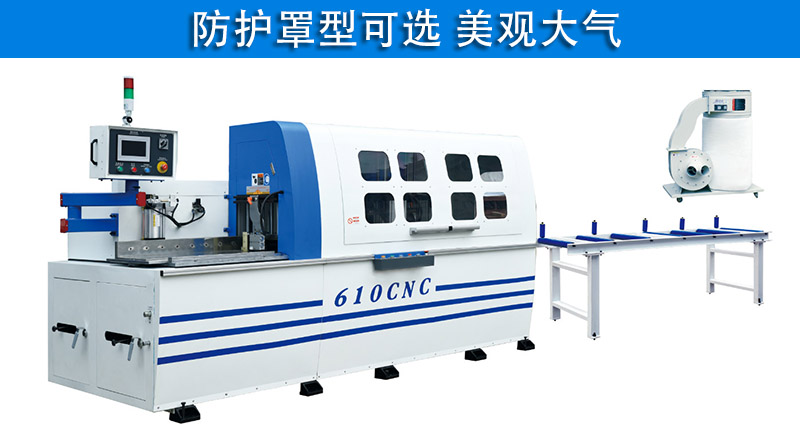

Summary: YJ-610CNC adopts advanced numerical control and hydraulic technology. The product has high precision, smooth and smooth sawing end face, stable performance, simple operation, durable, professional quality and trustworthy!

| Model | YJ-610CNC |

| Servo drive system | Ball screw |

| Sawing ability | H x W 200 x200mm, 175 x210mm, 130 x350mm, 20x400mm depending on the size of the saw blade, such as the sawing capacity diagram (optional H200 x W400) |

| Automatic feeding stroke | 1350mm (optional 3000/6000mm) can be fed over |

| Automatic feeding accuracy | ± 0.1mm |

| Saw blade spindle speed | 1500-3500R.P.M. Stepless speed change (can be set according to the actual blade size) |

| Saw blade spindle horsepower | 15 HP (Optional 15 HP Level 4) |

| Spindle variable frequency motor | 15 HP (optional 20 HP) |

| Oil pressure into the horsepower | 1 HP |

| Servo motor horsepower | 1.5kw |

| Touch screen | 5.7" |

| Saw blade size | 12", 14", 16", 18", 20", 22", 24" (1" aperture) |

| Air pressure | 4 - 6kgs / cm² |

| Mechanical Dimensions | 3500 x 2100 x 1860 mm |

| Packing size | 3620 x 2220 x 2000 mm |

| Mechanical weight | 2300kgs |

| Packing weight | 2700kgs |

scan it

scan it scan it

scan it